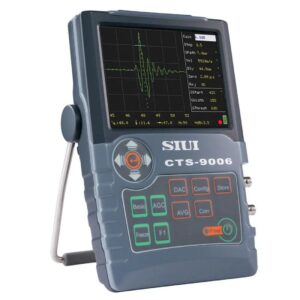

Flaw Detectors, Non-Destructive Testing Equipment (NDT)

Ekko Palmtop Ultrasonic Flaw Detector

- Lightweight palmtop unit weighing 1.75 Lbs (800 gms) including battery

- User-friendly menu navigation

- High resolution (800 x 480 pixels) WVGA display

- Removable Micro SD card up to 8 GB

- USB communication port

- Auto plotting dynamic DAC

- On-Board DGS/AVG for defect size evaluation

- Software for AWS D1.1 Sizing

- Test Range in steel: 0.10” (2.5mm) to 200” (5 M)

- Square Wave Pulser

22,000.00 AED 25,882.00 AED

Brand: Ekko

Non-Destructive Testing Equipment In Dubai

The EKKO+ digital ultrasonic flaw detector by JMD, USA, is a high-precision non-destructive testing (NDT) equipment in Dubai, UAE, designed for detecting flaws in metals, composites, and plastics. Using advanced ultrasound technology, it ensures accurate inspections with real-time data analysis and customisable settings. Its user-friendly interface and portability make it ideal for professionals in manufacturing, construction, and quality assurance. This reliable NDT device enhances flaw detection efficiency, ensuring superior quality control across various industries.

| Test Range: | 0.10” (2.5mm) to 200” (5 M) in steel. Fine mode adjustable in step of .04″ (1mm) |

| Velocity: | 0.03” (1000 m/s) to 0.59”/μs (15000 m/s). In Hot Key mode it has 7 present values. Fine mode adjustable in step of 3.9”/µs (1 m/s) |

| Delay: | Up to 120” (3 meter) adjustable in 0.01” (0.5 mm) or 0.2” (5 mm) step |

| Gain: | 100 dB calibrated gain adjustable in 0.5 | 1 | 2 | 6 or 14 dB step |

| Rejection: | 0 to 125% FSH with LED indicator |

| Rectification: | Full wave rectified with filtering |

| Frequency: | 0.5 MHZ to 15 MHZ (wide band) |

| Linearity deviation: | Vertical +3% Horizontal +0.5% |

| est Modes: | Pulse echo and transmit/receive |

| Measuring Resolution : | 0.004″ (0.01mm) |

| Connectors : | Lemo Size 00 (2 Nos) |

| Monitor: | Dual gate adjustable in 1% of Screen width with Positive/Negative logic | Gate Expand modes |

| Gate Expand: | Expands Range to width of the gate |

| A-Scan Memory : | 500 Trace Patterns can be stored | recalled or transferred to PC via USB port A-Scan trace pattern can be directly stored on SD card or on External USB disk |

| Calibration Set-up: | 50 different calibration set-ups can be Stored and Recalled |

| Software: | EkkoSoft Interface software for transferring A-Scan from Ekko to PC is supplied |

| USB & SD Card: | External USB disk & Micro SD card (up to 8GB) ports provided for data storage |

| Display: | 5” Color Wide VGA LCD/TFT display (800 mm x 64 mm) with higher resolution LCD for better signal representation & better visibility with different color sets |

| DGS: | Defect size evaluation using predefined probe settings and custom probe set-ups | ERS (Equivalent Reflector Size) can also be displayed on the screen |

| AWS: | Built in Software for Evaluation of defects in accordance with AWS Specification D1.1 |

| Update Rate: | 50 Hz |

| Power: | Lithium-ion Battery pack 7.4VDC | 4AH gives 4 hours continuous operation from fully charged battery Additional one extra battery with external charger provided to enable back to back 8 hours operation |

| Charger: | Input Voltage 100 to 240 VAC (with in-built charge status indicator) |

| Temperature: | 32 F to 131 F (0 C to 55 C)0.00000000000000000000000000000000000000 |

There are no reviews yet.